As Europe continues to deliver larger and more complex infrastructure projects involving major waterways, project towage is increasingly shaping how and when construction moves forward. What was once treated as a supporting marine service has now become a highly specialised discipline.

According to Jan-Andries Arts, Commercial Manager at Multraship Towage & Salvage, the most notable shift in recent years has been driven by the increasing complexity of these projects.

“As projects become more complex, there is a growing demand for combined project scopes,” he explains. “Clients are not only chartering tugs, multicats, and other specialised equipment, including floating sheerlegs such as CORMORANT, but are also increasingly relying on qualified and highly experienced towmasters. These towmasters play a central role in validating methods, training crews and coordinating operations during the execution phase.”

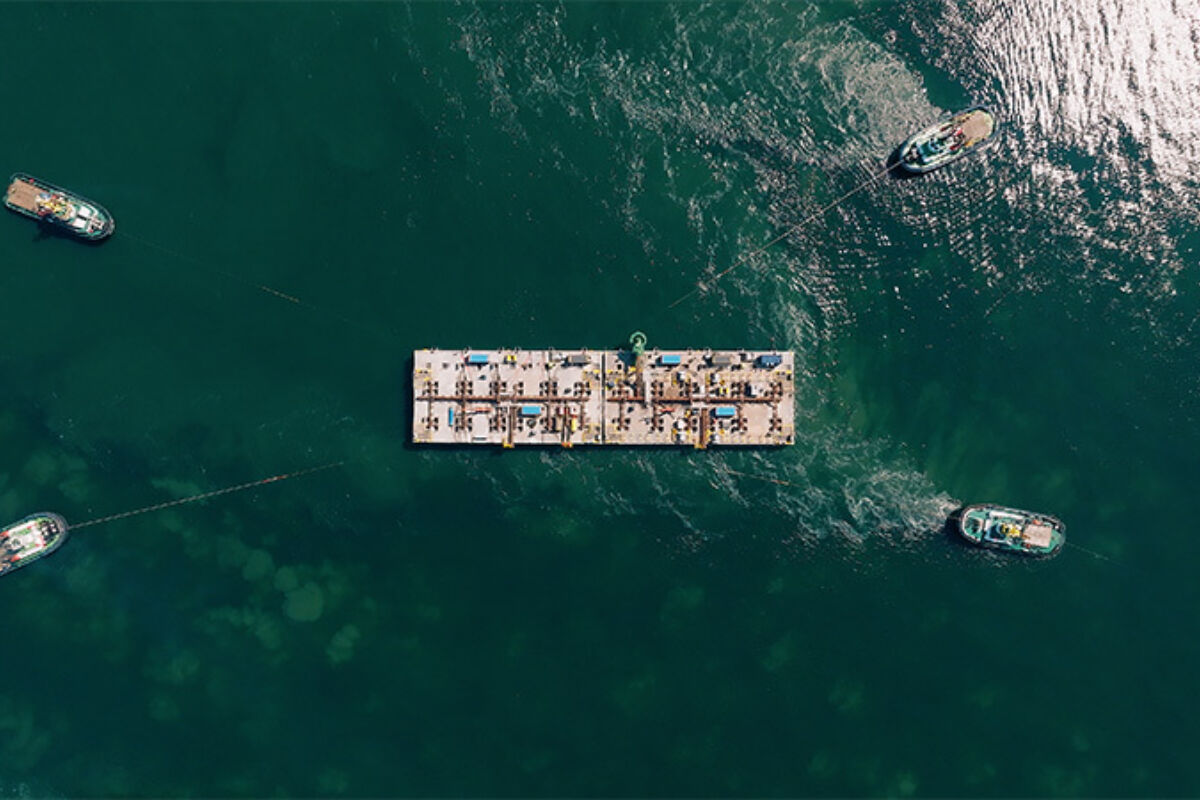

This evolution is reflected in two recent northern European projects involving Multraship, where original towing scopes expanded as requirements developed. The first was the new Scheldt Tunnel in Antwerp, Belgium, a key part of the Antwerp Ring Road. In 2025, eight concrete tunnel elements, each weighing around 60,000 tonnes, were successfully delivered and immersed. The second project involved the delivery and installation of the first phase of Princess Elisabeth Island in the North Sea, where 11 of 23 concrete caissons, each weighing more than 22,000 tonnes, formed the island’s outer walls. Phase two is set to begin in spring 2026.

While each project presented different challenges, from operating in congested inland waterways to installing structures more than 24 nautical miles offshore, both demonstrated how detailed and complex modern infrastructure towage has become. For the Scheldt Tunnel, 160 m-long elements were towed almost 60 nautical miles from Zeebrugge before being positioned within shore-based winch systems during immersion. At Princess Elisabeth Island, the caissons required millimetre precision to create a secure, watertight structure.

Preparation was critical. Towmasters and vessel masters simulated operational phases to assess methods, mitigate risks, and establish realistic timeframes.

“To ensure we were as prepared as possible, Multraship’s methods were further developed into detailed and phase-specific planning, based on weather patterns, currents, tidal conditions and other environmental factors,” Arts noted.

“Towmasters need to know when and how to deviate from the original scenario if there are immediate changes to weather conditions. We deliberately test and simulate these types of scenarios ahead of any major project to ensure we are aware of and able to handle any and all potential risks. The potential outcome if simulations didn’t take place could be catastrophic,” he added.

Coordination with authorities, pilots, and other stakeholders formed another key element. Early engagement ensured methods were compliant, workable, and safe, while maintaining maximum waterway availability in dense transport areas.

“We support our clients as fully as possible in order to achieve a technically and operationally workable solution,” Arts explains.

Despite extensive preparation, flexibility during execution remained essential. Weather windows closed unexpectedly, requiring rapid rescheduling and placing high demands on towmasters and coordinators.

“On more than one occasion, we had last-minute cancellations due to weather, where we had to reschedule all operations in record time,” Arts noted.

As Europe’s infrastructure continues to expand offshore and beneath major waterways, project towage is evolving into a core element of construction delivery, defined by early technical involvement, strict method discipline, and experienced operational leadership.